Product Certification

UL Listed / FM Approved (EX 26523)

Material of Construction

Ductile Iron as per ASTM A536 Gr. 65 – 45 – 12

Pressure Rating

Test Pressure : 12.5 MPa

Max. Working Pressure : 2.5 MPa

Please note that as per FM 1920:2007 Sizes <= 150 mm are rated PN20 and > 150 mm are rated PN16

Nuts & Bolts

Heat Treated Carbon Steel as per ISO 898-1 Class 8.8

Finishing

Epoxy Red Paint RAL – 3000/3001

Branch Outlets

Threaded Branch Outlets as per BSPT ISO 7-1

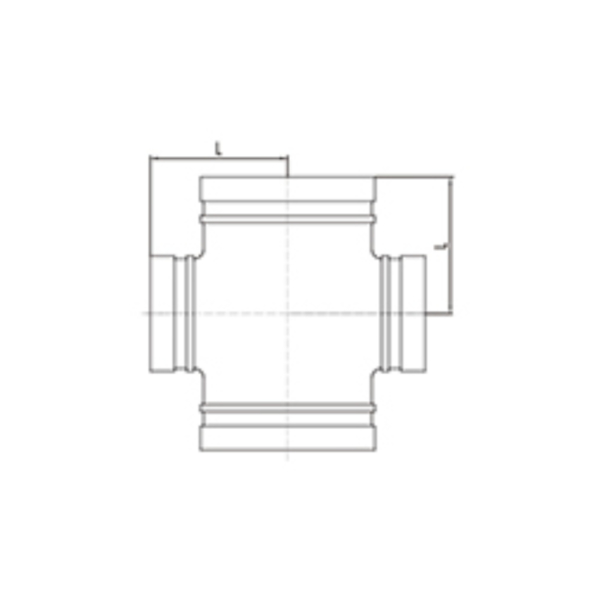

| Nominal Size | Nominal Size (Inch) | Pipe O.D. | L |

|---|---|---|---|

| 50×40 | 2×1.1/2 | 60.3×48.3 | 70 |

| 65×25 | 2.1/2×1 | 76.1×33.7 | 70 |

| 65×32 | 2.1/2×1.1/4 | 76.1×42.4 | 70 |

| 65×40 | 2.1/2×1.1/2 | 76.1×48.3 | 70 |

| 65×50 | 2.1/2×2 | 76.1×60.3 | 70 |

| 80×25 | 3×1 | 88.9×33.7 | 86 |

| 80×32 | 3×1.1/4 | 88.9×42.4 | 86 |

| 80×40 | 3×1.1/2 | 88.9×48.3 | 86 |

| 80×50 | 3×2 | 88.9×60.3 | 86 |

| 80×65 | 3×2.1/2 | 88.9×76.1 | 86 |

| 100×25 | 4×1 | 114.3×33.7 | 102 |

| 100×32 | 4×1.1/4 | 114.3×42.4 | 102 |

| 100×40 | 4×1.1/2 | 114.3×48.3 | 102 |

| 100×50 | 4×2 | 114.3×60.3 | 102 |

| 100×65 | 4×2.2/1 | 114.3×76.1 | 102 |

| 100×80 | 4×3 | 114.3×88.9 | 102 |

| 125×25 | 5×1 | 139.7×33.7 | 122 |

| 125×32 | 5×1.1/4 | 139.7×42.4 | 122 |

| 125×40 | 5×1.1/2 | 139.7×48.3 | 122 |

| 125×50 | 5×2 | 139.7×60.3 | 122 |

| 125×65 | 5×2.1/2 | 139.7×76.1 | 122 |

| 125×80 | 5×3 | 139.7×88.9 | 122 |

| 125×100 | 5×4 | 139.7×114.3 | 122 |

| 150×25 | 6×1 | 165.1×33.7 | 140 |

| 150×32 | 6×1.1/4 | 165.1×42.4 | 140 |

| 150×40 | 60×1.1/2 | 165.1×48.3 | 140 |

| 150×50 | 6×2 | 165.1×60.3 | 140 |

| 150×65 | 6×2.1/2 | 165.1×76.1 | 140 |

| 150×80 | 6×3 | 165.1×88.9 | 140 |

| 150×100 | 6×4 | 165.1×114.3 | 140 |

| 150×125 | 6×5 | 165.1×139.7 | 140 |

| 200×50 | 8×2 | 219.1×60.3 | 175 |

| 200×65 | 8×2.1/2 | 219.1×76.1 | 175 |

| 200×80 | 8×3 | 219.1×88.9 | 175 |

| 200×100 | 8×4 | 219.1×114.3 | 175 |

| 200×125 | 8×6 | 219.1×139.7 | 175 |

| 200×150 | 8×6 | 219.1×165.1 | 176 |

| 250×80 | 10×3 | 273×88.9 | 215 |

| 250×100 | 10×4 | 273×114.3 | 215 |

| 250×125 | 10×5 | 273×139.7 | 215 |

| 250×150 | 10×6 | 273×165.1 | 215 |

| 250×200 | 10×8 | 273×219.1 | 215 |

XGQT1

Rigid Coupling

XGQT2

Flexible Coupling

XGQT01

90° Elbow

XGQT02

45° Elbow

XGQT021

22.5° Elbow

XGQT022

11.25° Elbow

XGQT03

Equal Tee

XGQT05

Equal Cross

XGQT04

Reducing Tee (Grooved)

XGQT04S

Reducing Tee (Threaded)

XGQT051

Reducing Cross (Grooved)

XGQT3

Mechanical Tee (Grooved)

XGQT3S

Mechanical Tee (Threaded)

XGQT3U

U-Bolted Mechanical Tee (Threaded)

XGQT08

Flange Adaptor PN16

XGQT18

Grooved Flange PN16

XGQT07

Concentric Reducer (Grooved)

XGQT07S

Concentric Reducer (Threaded)

XGQT17

Eccentric Reducer (Grooved)

XGQT06

Cap

-

Cap with Eccentric Hole